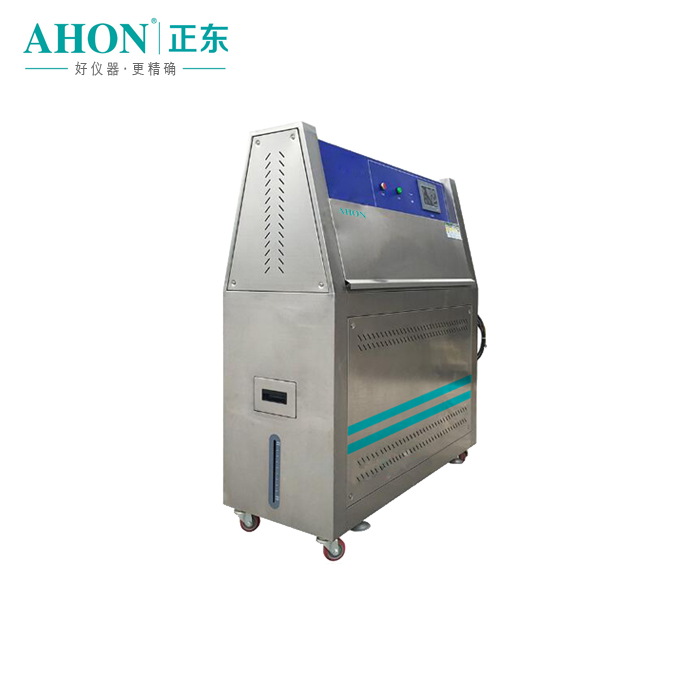

E-L02K Series Rubber Anti-UV Aging Test Box mainly used to simulate the destructive hazards caused by sunlight, rainwater and dew on products or materials. used fluorescence uv lamp to simncate by sunshine lllumination effects using cold moist rain and dew. The tested material is placed in a cyclic program of alternating light and moisture at a certain temperature for testing. The hazard test analysis occurring outdoors for months to years can be reproduced by several days or weeks of UV testing