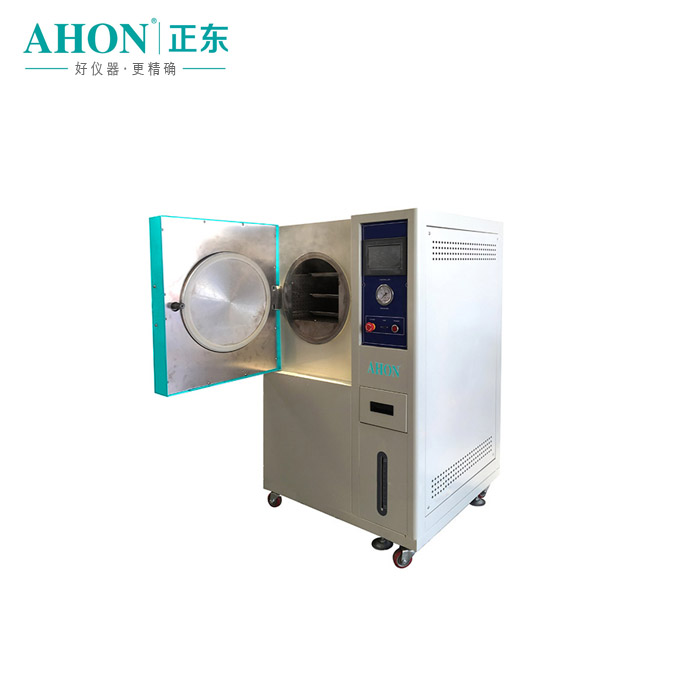

It is mainly used to simulate the destructive harm of sunlight, rainwater and dew to products or materials. It uses fluorescent ultraviolet (UV) lamp to simulate the effect of sunlight irradiation, and cold moist rain and dew. The tested material is placed in a cyclic program of alternating light and moisture at a certain temperature for testing. The harmful test analysis which appears in the outdoor environment for months to years can be reproduced by UV testing for several days or weeks. Harm