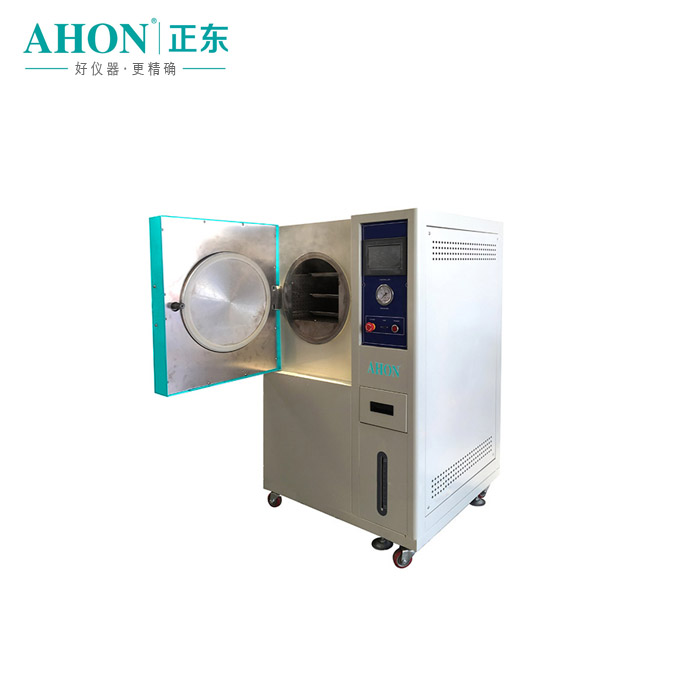

E-L01D Series Large High Temperature Aging Room using the latest technology development, technical expert team on the product appearance form, transport control system, functional structure, human-computer interaction and other cutting-edge industrial science applications for integrated optimization design, the use of new technology will be the production process digitization, intelligent, strict factory standard performance testing, Intelligent test and Analysis system software (Chinese and English bilingual model) and high-performance original imported key components, so that it has a strong high-speed data acquisition and large-scale analysis and processing capabilities, more improve the accuracy of test values, to provide users with more accurate operation, more standard, more efficient instruments and equipment.

1. Product Use

E-L01D Series Large High Temperature Aging Room

It is mainly used to simulate the aging test of the whole machine, components, electrical appliances, instruments, materials and other export products that need to be exported by sea in containers under high temperature environmental conditions, so as to evaluate the adaptability test of the transportation process of the test products.

1) Applicable to aging life test of automobile electronics, communication products, PCB, consumer electronics and other products;

2) Suitable for aging test of computer board, interface card, plug-in card, mobile phone, power supply and other products;

3) Applicable to set-top box, highway alarm phone, security and other products burning machine test;

3) Applicable to set-top box, highway alarm phone, security and other products burning machine test;

2.Fields of Application

Applicable to aerospace, defense industry, high-end equipment, electronic and electrical appliances, communications equipment, automotive manufacturing, trams, petrochemicals, biomedicine and other enterprise units, or key laboratories, colleges and universities, scientific research institutions, quality supervision institutions and other professional fields of use.

3..Structure Features

1) Vacuum Electrothermal Film Observation window observation of bright and clear field of view, without wiper defogging, can be seen at any time the status of the test product;

2) Control system integrated design function control cabinet, aging time, temperature, all kinds of operating switches can be operated on a control cabinet; easy to operate.

3) Automatically control the aging process, automatically cut off the power supply such as circulating fan and electric heating, with some abnormal self-treatment functions, so that the operation is automated and simplified.

4) The aging room cools itself and continues to aging. The aging test is completed when the aging time is set and the yellow warning light is turned on.

4.Implementation Standard

1)GB/T5170.2-2008 temperature test equipent

2) GB/T5170.5-2008 humid and hot test equipent

3) GB/T2423.1-2008(IEC60068-2-1:2008)Low Temperature test method Ab ;

4) GB/T2423.2-2008(IEC60068-2-2:2008)high temperature test method Ab;

5) GB/T2423.3-2008(IEC60068-2-78:2008 Constant heat and humdity test method

6) GB/T2423.4-2008(IEC60068-2-30:2008)alternating heat and humidity test method;

7) IEC60068-2-14 2009 surrounding test .part 2-14Tests .Chamge Of Ntemperature in test.