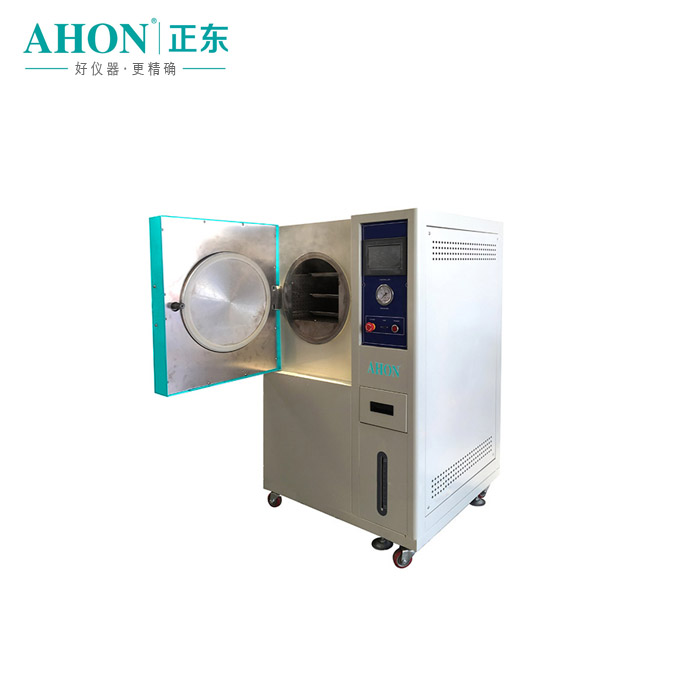

E-L01B series Walk-in High Temperature Aging Room mainly used for equipment whole machine or low temperature for large parts、high temperature, high and low temperature change, constant heat, high and low temperature alternating heat and heat, resistance,Moisture resistance and other performance Provide users with large-scale test environment space for large parts, semi-finished products and finished products.