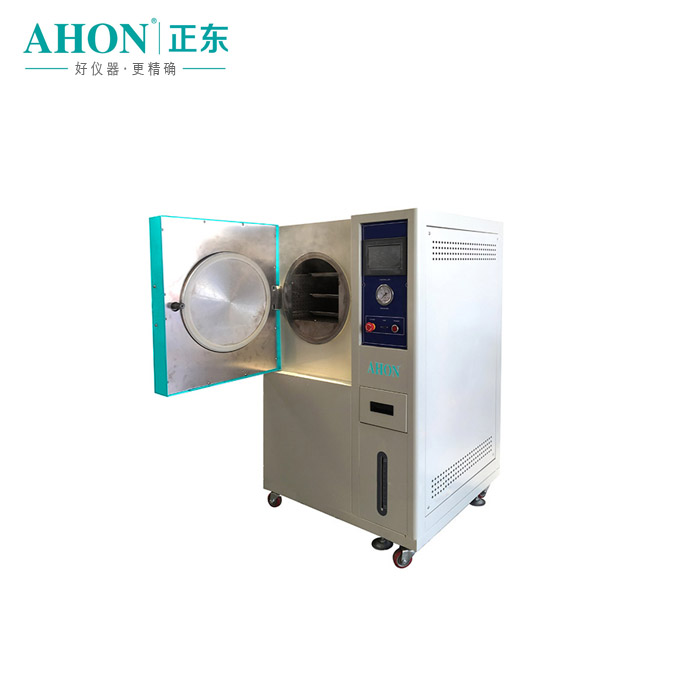

PCT test is generally called pressure cooker cooking test or saturated steam test.E-L07A series PCT high-pressure accelerated aging test box is to test the tested products under harsh temperature, saturated humidity (100% R.H.), saturated water vapor and pressure environment, to test the high humidity resistance of the tested products, to test the wear resistance and air tightness of the products, and to quickly expose the defects and weak links of the products for destructive testing. Inspectio