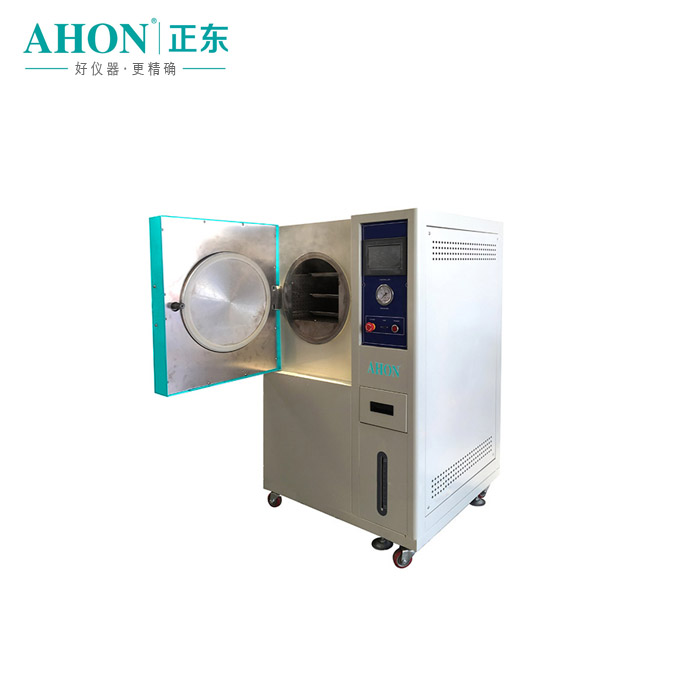

HAST Unsaturated High Pressure Acceleration Testing Machine mainly used for testing many product design and finished product stages, such as electronic components, photovoltaic solar modules, automotive parts, metals, plastics, BGA, PCB-based wrenches, electronic chip IC, semiconductor, chemical materials, polymer materials, etc. It can simulate the visible atmosphere environment at the same time in a HAST high-pressure accelerated aging test process. Factors such as light, oxygen, heat and rain