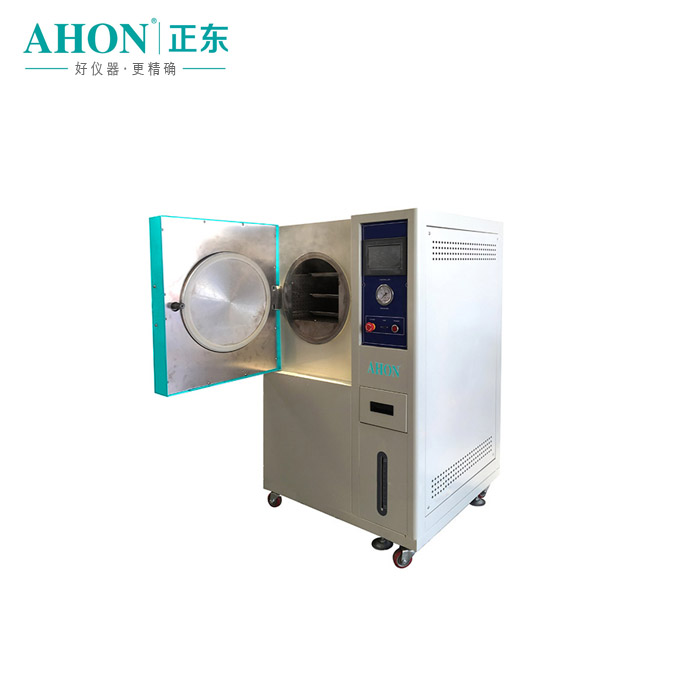

Hardware Steam Aging Testing Machine using the latest technology development, technical expert team on the product appearance form, transport control system, functional structure, human-computer interaction and other cutting-edge industrial science applications for integrated optimization design, the use of new technology will be the production process digitization, intelligent, strict factory standard performance testing, Intelligent test and Analysis system software (Chinese and English bilingual model) and high-performance original imported key components, so that it has a strong high-speed data acquisition and large-scale analysis and processing capabilities, more improve the accuracy of test values, to provide users with more accurate operation, more standard, more efficient instruments and equipment.

1. Product Use

Hardware Steam Aging Testing Machine mainly used for parts, metal materials and materials to test the physical and other related properties of products under simulated high temperature, high temperature, high humidity and pressure climate conditions. After testing, the performance of products can be judged by verification, so as to provide for product design, improvement, verification and factory quality inspection. Technical Standard Test of the test.

Applicable to electronic connectors, semiconductor IC transistors, diodes, liquid crystal LCD, hardware plating, plastic plating, hardware products, metal products, electronic appliances, electronic hardware, hardware plastics, chemical paint, automobile parts, bicycle parts, bathroom sanitary ware, plumbing equipment, bolt fasteners, etc. Accelerated Life Time Test Assessment of Oxidation, Fatigue Aging, Performance Degradation and Corrosion of Magnetic Materials, Lock Making Industry, Hardware Furniture and Sports Equipment

2.Fields of Application

Applicable to aerospace, defense industry, high-end equipment, electronic and electrical appliances, communications equipment, automotive manufacturing, trams, petrochemicals, biomedicine and other enterprise units, or key laboratories, colleges and universities, scientific research institutions, quality supervision institutions and other professional fields of use

3.Structure Features

1) Adopting PID+SSR temperature controller, it has high precision and stable control.

2) Multiple safety protection devices, fault alarm display and function display of fault causes and troubleshooting methods

3) Simple operation setting, digital LED control, time setting function, maximum setting 9,990 Mins;

4) Using large capacity water tank, long test time, automatic replenishment when water level is too low, to ensure the uninterrupted test

5) The imported color programmable touch screen is used to configure USB curve data download function and communication function.

6) High-efficiency vacuum pump is used to achieve the best pure saturated vapor state in the box.

7) the bottom of the machine is fixed wih anti-vibrtion adhesive

4、Implementation Standard

1)conforms to GB/T14831 test standard

2)conforms to MTL-SIP-208F、202GB、GJB、MIL、ASTM、CNS、IES、JIS test standard