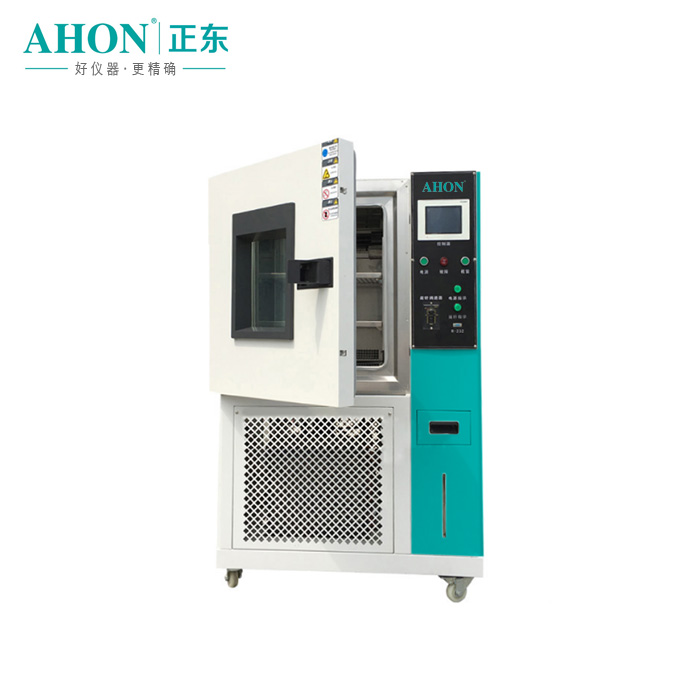

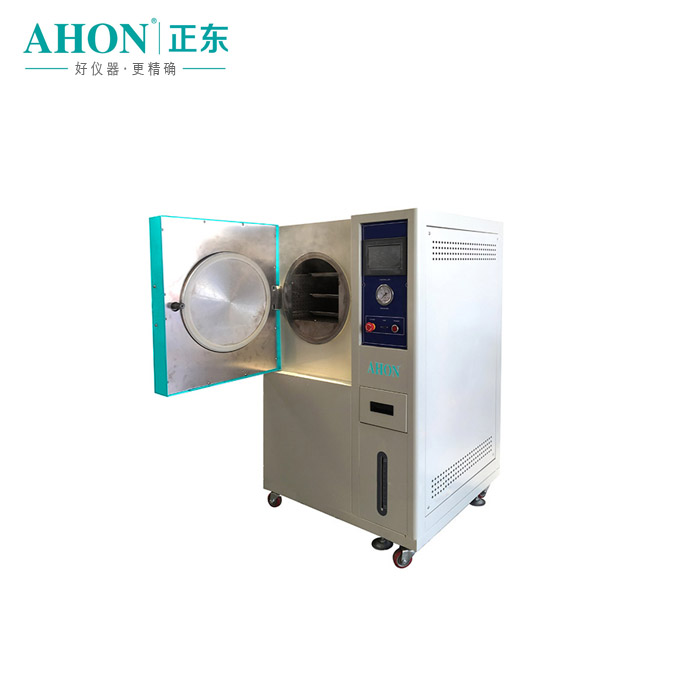

E-L04A Series Ozone Aging Test Box mainly used to test the ozone aging resistance of polymer materials and products. The low ozone content in the atmosphere is the main factor for rubber cracking. By simulating and strengthening the ozone conditions in the atmosphere, the experimental results which are similar to the actual use or reproducible in a short time are obtained, and the effect of ozone on polymer materials and products is studied. The aging regularity of rubber products, the methods o